Ferrous Fumarate USP BP Ph Eur

Annie Chemie Pvt. Ltd, is a pioneer manufacturer and exporter of Specialty chemicals, oil field shale gas fracking or hydraulic fracturing chemicals, Located at Dahej in Gujarat, India. Annie Chemie Pvt. Ltd, has manufacturing facilities and associates spread across USA, Canada, Russia, Europe, UAE, Nigeria, Algeria, Turkey, Mexico, Brazil, Chile, Argentina, Australia, Dubai etc.

Specifications of Ferrous Fumarate BP Grade Ph Eur

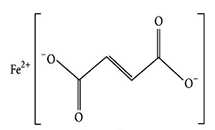

C4H2FeO4 --- 169.9 --- CAS 141-01-5

DEFINITION

Iron (II) (E)-butenedioate.

Content: 93.0 per cent to 101.0 per cent (dried substance).

CHARACTERS

Appearance: Fine, reddish-orange or reddish-brown powder.

Solubility: Slightly soluble in water, very slightly soluble in ethanol (96 per cent).

IDENTIFICATION

A. Thin-layer chromatography.

B. Mix 0.5 g with 1 g of resorcinol R. To 0.5 g of the mixture in a crucible add 0.15 ml of sulphuric acid R and heat gently. A dark red semi-solid mass is formed. Add the mass, with care, to 100 ml of water R. An orange-yellow colour develops and the solution shows no fluorescence.

C. The filtrate obtained during preparation of the test solution in identification test A gives reaction (a) of iron (2.3.1).

TESTS

Solution S: Dissolve 2.0 g in a mixture of 10 ml of lead-free hydrochloric acid R and 80 ml of water R, heating slightly if necessary. Allow to cool, filter if necessary and dilute to 100 ml with water R.

Sulphates: Maximum 0.2 per cent.

Arsenic: Maximum 5 ppm.

Ferric ion: Maximum 2.0 per cent.

Cadmium: Maximum 10.0 ppm.

Chromium: Maximum 2.00 × 102 ppm.

Lead: Maximum 20.0 ppm.

Mercury: Maximum 1.0 ppm.

Nickel: Maximum 2.00 × 102 ppm.

Zinc: Maximum 5.00 × 100 ppm.

Loss on drying: Maximum 1.0 per cent, determined on 1.000 g by drying in an oven at 105C.

Specifications of Ferrous Fumarate USP Grade

C4H2FeO4 --- 169.90

2-Butenedioic acid, (E)-, iron(2+) salt.

Iron(2+) fumarate CAS 141-01-5

Identification:

A: To 1.5 g add 25 mL of dilute hydrochloric acid (1 in 2). Dilute with water to 50 mL, heat to dissolve, then cool, filter on a fine-porosity, sintered-glass crucible, wash the precipitate with dilute hydrochloric acid (3 in 100), saving the filtrate for Identification test B, and dry the precipitate at 105C: the IR absorption of a potassium bromide dispersion of the dried precipitate so obtained exhibits maxima only at the same wavelengths as that of a similar preparation of USP Fumaric Acid RS.

B: A portion of the filtrate obtained in the preceding test responds to the tests for Iron.

Loss on drying: Dry it at 105C for 16 hours: it loses not more than 1.5% of its weight.

Sulfate: Transfer 1.0 g to a 250-mL beaker, add 100 mL of water, and heat on a steam bath, adding hydrochloric acid drop wise, until complete solution is effected (about 2 mL of the acid will be required). Filter the solution if necessary, and dilute the filtrate with water to 100 mL. Heat the filtrate to boiling, add 10 mL of barium chloride TS, warm on a steam bath for 2 hours, cover, and allow to stand for 16 hours. (If crystals of ferrous fumarate form, warm the solution on the steam bath to dissolve them.) Pass the solution through ash less filter paper, wash the residue with hot water until, with the addition of ammonium sulfide TS, a black precipitate is no longer formed in the filtrate, and transfer the paper containing the residue to a tared crucible. Char the paper, without burning, and ignite the crucible and its contents at 600 to constant weight: each mg of residue is equivalent to 0.412 mg of SO4. Not more than 0.2% is found.

Arsenic: Transfer 2.0 g to a beaker, and add 10 mL of water and 10 mL of sulfuric acid. Warm to precipitate the fumaric acid completely, cool, add 30 mL of water, and filter into a 100-

mL volumetric flask. Wash the precipitate with water, adding the washings to the flask, add water to volume, and mix. Transfer 50.0 mL of this solution into the arsine generator flask, and dilute with water to 55 mL: the resulting solution meets the requirements of the test, the addition of 20 mL of 7 N sulfuric acid specified for Procedure being omitted. The limit is 3 ppm.

Limit of ferric iron: Transfer 2.0 g, accurately weighed, to a glass-stoppered, 250-mL conical flask, add 25 mL of water and 4 mL of hydrochloric acid, and heat on a hot plate until solution is complete. Insert the stopper in the flask, and cool to room temperature. Add 3 g of potassium iodide, insert the stopper in the flask, swirl to mix, and allow to stand in the dark for 5 minutes. Remove the stopper, add 75 mL of water, and titrate with 0.1 N sodium thiosulfate VS, adding 3 mL of starch TS as the end-point is approached. Not more than 7.16 mL of 0.1 N sodium thiosulfate is consumed (2.0%).

Limit of lead: To pass the atomic absorption spectrophotometer test. The Test solution does not exceed that of the Standard solution (0.001%).

Mercury: To pass the test of 3 µg per g.

Ferrous Fumarate IP Grade

Specifications of Ferrous Fumarate FCC Food Grade

Iron (II) Fumarate FCC

C4H2FeO4 --- Formula weight 169.90 --- CAS 141-01-5

DESCRIPTION

Ferrous Fumarate occurs as a red-orange to red-brown powder. It may contain soft lumps that produce a yellow streak when crushed. It is soluble in water and in alcohol.

Function: Nutrient.

REQUIREMENTS

Identification:

A. Add 25 mL of 1:2 hydrochloric acid to about 1.5 g of sample, and dilute to 50 mL with water. Heat to effect complete solution; then cool; filter on a fine-porosity, sintered glass crucible; wash the precipitate with 2:100 hydrochloric acid, saving the filtrate for Identification Test B; and dry the precipitate at 105C. Add 3 mL of water and 7 mL of 1 N sodium hydroxide to 400 mg of the dried precipitate, and stir until solution is complete. Add, drop wise, 2.7 N hydrochloric acid until the solution is just acid to litmus; add 1 g of pnitrobenzyl

bromide and 10 mL of alcohol; and reflux the mixture for 2 h. Cool, filter, and wash the precipitate with two small portions of a 2:1 alcohol:water mixture, followed by two small portions of water. The precipitate, recrystallized from hot alcohol and dried at 105°C, melts at about 152C.

B. A portion of the filtrate obtained in Identification Test A gives positive tests for Iron.

Assay: Not less than 97.0% and not more than 101.0% of C4H2FeO4, calculated on the dried basis.

Ferric Iron: Not more than 2.0%.

Lead: Not more than 2 mg/kg.

Loss on Drying: Not more than 1.5%.

Mercury: Not more than 3 mg/kg.

Sulfate: Not more than 0.2%.